Care of 19th century prints in the National Library of the Czech Republic

Keywords: preservation, restoration, 19th century prints, binding, lignin containing paper

Ing. Petra Vávrová, Ph.D., Tereza Kašťáková, Mgr. Jitka Neoralová, Ing. Kristýna Boumová, Tereza Sazamová1 / The National Library of the Czech Republic, Centrální depozitář v Hostivaři, Sodomkova 2, Praha 1

Introduction

The Collection Preservation Division of the National Library of the Czech Republic (hereinafter NL CR) has devoted special attention to the care also of the so-called modern library collections, which contain books and documents created within the range of last more than two hundred years, beginning 1801, down to the present day, among its recent activities of the last five years. These collections record development of Czech culture and national entity – they have invaluable historical, art, and social significance, and principal informative value. Unfortunately, the material from which the prints were produced after 1845 - lignin containing paper - as well as present changed technologies and materials, result in their poor durability. At the same time, this durability affects a number of degradation factors, above all external factors, which are ambient temperature, relative air humidity, impurities included in environment (e.g. dust particles, air-borne pollutants such as oxides of sulphur and nitrogen, ozone, etc.), light energy, biological pests (mildew, bacteria, insects), etc.

Poor quality of materials of modern book collections is accompanied even with large quantity of documents in this segment of collections: in the National Library CR, there is up to 96 % of book collections, whereas their contents still increases.

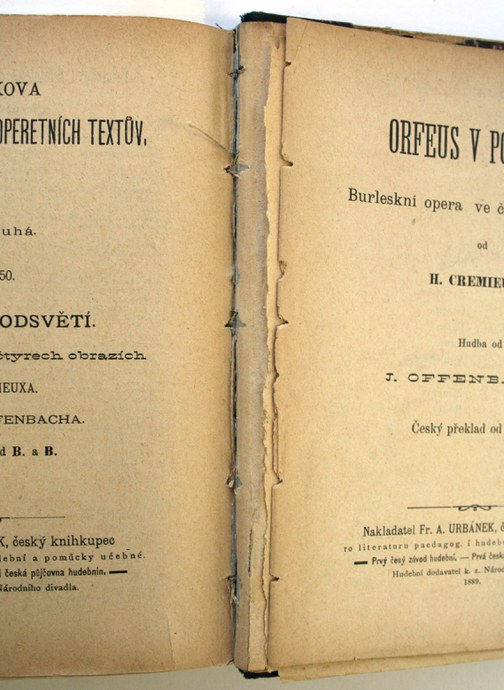

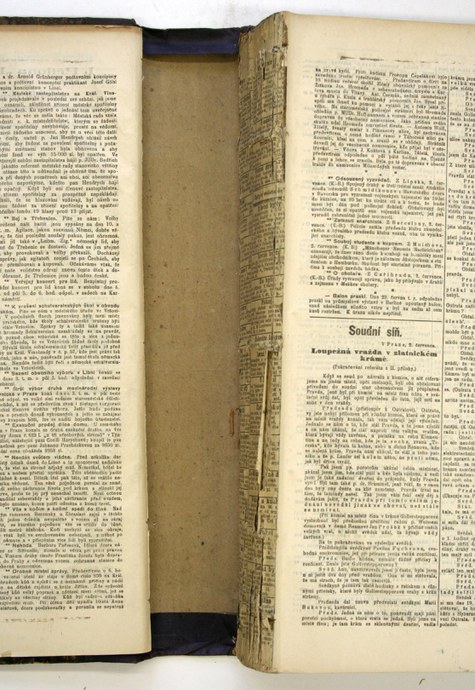

In term of care of modern collections we focused on the 19th century collections because of their rarity and uniqueness. The 19th century prints also contain variety of materials.

After brief description of prints condition this paper focus on methods of cleaning, preservation, and restoration modern prints also the specific aspects of textile covers of the 19th century books.

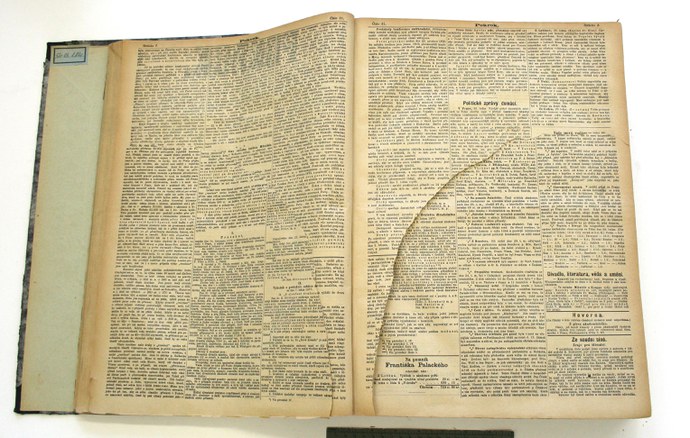

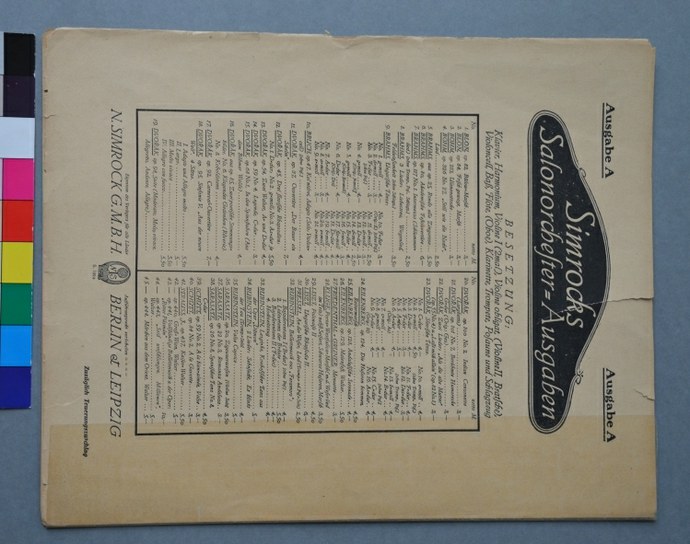

19th century documents

The electronic "Bibliography of the 19th century" (available on NL CR web 2) includes 97,161 scanned cards. The Union catalogue of the national retrospective bibliography of the 19th century contains prints in the Czech language without territorial restriction from 1801–1900 from Prague and off-Prague libraries with denotation of sites of their occurrence. It also registers small prints (almanacs, calendars, annual reports, concert and theatre programs), however, it does not contain newspapers and magazines from this period. Sequencing the entries is in alphabetical order, in case of nameless pieces of work according to the directing noun. The records are not accessible through OPAC (ALEPH system).3

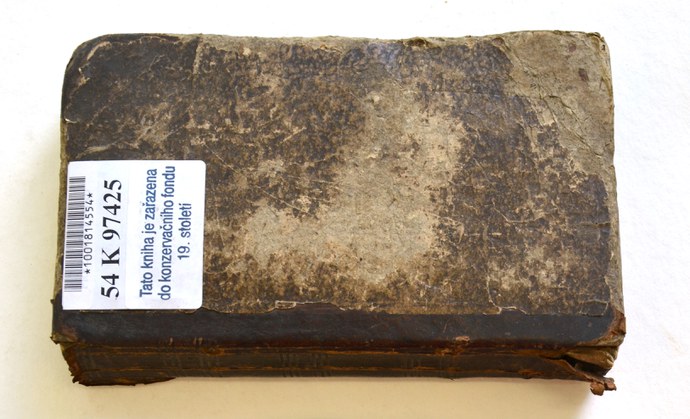

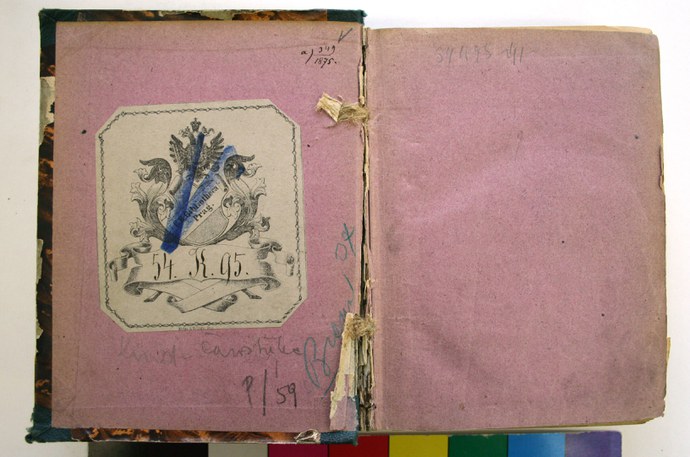

In categorization of book collections, the disproportion is manifested at the level of protection among newer documents from 1901 to the present and documents of the 19th century. In the first case the National Library CR obtained two obligatory copies (OC) one of which was of an archive character, meaning that its circulation was very limited (these segments of collections of NL CR are marked OC I). In case of the 19th century documents, one obligatory copy was in the National Library CR only, or another copy obtained by purchase or as a gift, however, none of them had not an archive status, despite of the fact that these documents should be even better protected. In about 1998, the intention to set one copy apart was authorized by consultation of the management, and subject it to the same level of protection as OC I. Shortly after it, setting these documents apart was initiated and marking of the set apart copies. Setting apart was limited only to monographs. In case of periodicals, an additional analysis should be made, which would evaluate specificity of this type of documents and the impact of setting apart for services to users, or other areas of the library.

The intention declared that it does not concern change-over to the collection of the National Preservative Fund (NPF), but only under the management of the then Department of the National Preservation Collections, and integrity of the Universal Book Fund (UBF) thus remained preserved. The objective was to ensure the same level of protection to these documents as to those in the case of OC I. It was demonstrated already in implementation of the project financed from "The Norwegian Funds" focused on microfilming and digitization of monographs of the 19th century.4

Investigation of physical condition of 19th century prints

The above described extent of modern book collections only in the National Library CR alone exemplifies that also investigation of physical conditions of prints of the19th century must be drawn in a different way than that of older historical manuscripts and books. On the basis of experimental activities, a well-arranged and comprehensible application was created, "The Central knowledge base RD" 5,6, into which data found on physical conditions of individual copies has been recorded. The survey procedure of physical conditions of modern book collections was processed in methodology and it was certified.7

Up to now nobody has systematically dealt with targeted preservation or restoration of 19th century prints in NL CR nor in other libraries. From quantitative point of view, care for these collections requires above all another approach than that at restoration of older historical book collections – it is necessary to repair or preserve and fixate big quantities of books and documents of various material composition in a short time interval. Till this time, ethical and aesthetic standards for conservators´ interventions in modern collections have not been sufficiently worked out yet. Nowadays, care for modern library collections in the Czech Republic consists first of all in so-called preventive conservation, or setting climatic conditions (parameters given by standards for particular material of library objects), and conditions of depositing (e.g. wrapping and storage of books in acceptable covers, boxes, or envelopes, cleaning), or interventions of conservative character, bookbinding work, disinfection, in some case deacidification in order to decelerate degradation reactions of materials. Within the scope of project NAKI DF13P01OVV004 "Survey, conservation, and care for modern library collections – materials and technologies", procedures are being developed for preservation and restoration of bookbinding of particularly modern book collections, new more stable materials are also being developed for bookbinding and its repairs.

Textile covers of 19th century collections in the National Library CR

Textile covers of bookbinding appeared for the first time in connection with the industrial revolution at the beginning of 19th century. With extensive possibilities of printing and industrialization, branches of printers and publishers separated. Bookbinding already was the work of publishers, who laid stress on availability and quantity. Series publishing production came up. It resulted in rising pressure for depreciation both of services and materials. Quality of paper, printing, and also of artistic level of illustrations and graphic workmanship went down. From 1825, bookbinder's cloth, which is cheaper alternative to leather, began to expand from England.

Within the frame of project NAKI, we carried out a detailed survey of textile covers in more than 37 000 bindings from collections of the National Library CR in 2014. Over 4000 textile covers were documented using a camera and USB microscope. Frequency of both textile material bindings, and individual designs and surface finishes of bookbinder´s cloths were further assessed. Basis for the Technical University in Liberec, which develops new textile materials, was drafted out from this data. In cooperation with NL CR it develops procedures for restoration of canvas covers including possibility of completion of missing coat 8 and surface structures.

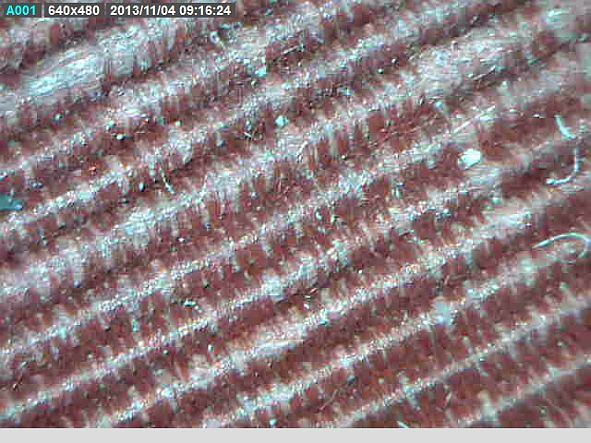

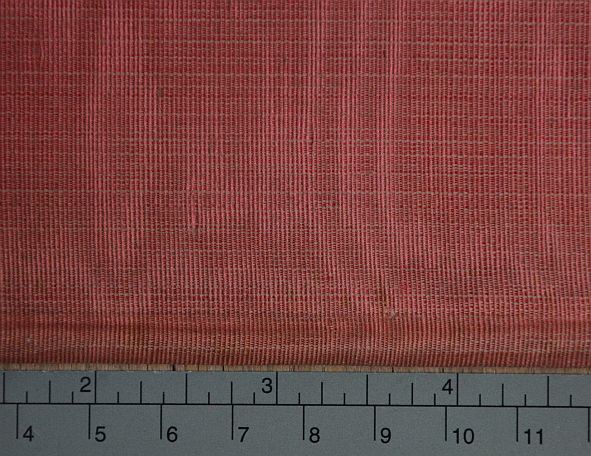

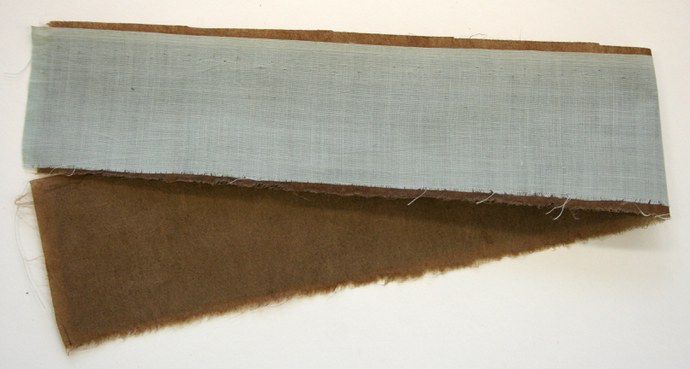

It is possible to find a number of various textile binding covers in collections of NL CR. The technological terms of half-cloth binding or whole-bound in cloth thus may mask considerable quantity of various materials and surface finishes of cover. For purposes of this survey we divided them into several groups and subgroups according to binding fabrics and, at the same time, according to surface finishes. Division according to surface finishes is commonly used in the nomenclature and division of book-binding cloths. It concerns fabrics with canvas weave (most often used), fabrics with twill weave, and finally satin fabrics, which appear very rarely (mostly in special bookbinding as albums, annual reports, visitors books, and likewise).9 Further, there are special sorts of fabrics, such as, for example, velvet. Some fabrics are manufactured by combination of more materials, when different threads are used for production of Warp, and others for woof (e.g. cotton or flax in combination with silk (Fig. 1)). Special effects of lights and lustre are achieved by that (Fig. 2).

Fig. 1 Photograph from microscope; combination of threads of various materials (Photo NL CR)

Fig. 2 Combination of materials (Photo NL CR)

It is necessary to point out that for labelling the textile cover in bookbinders´ nomenclature, denomination canvas is used regardless of whether the fabrics weave is plain weave or twill one.10 One talks different only about velvet, satin, and from it derived fabrics, as are brocades, damask or sateen.

Fabrics may be divided into three basic categories according to the method of thread weave. From each of these categories then comes out a number of variants, which already have their own commercial names.

Canvas

By plain weave we understand basic structure of fabrics, when thread texture regularly overlaps with woof always one over another (Fig. 3).

Fig. 3 Photograph from microscope; plain weave (Photo NL CR)

Fig. 4 Photograph from microscope; twill weave (Photo NL CR)

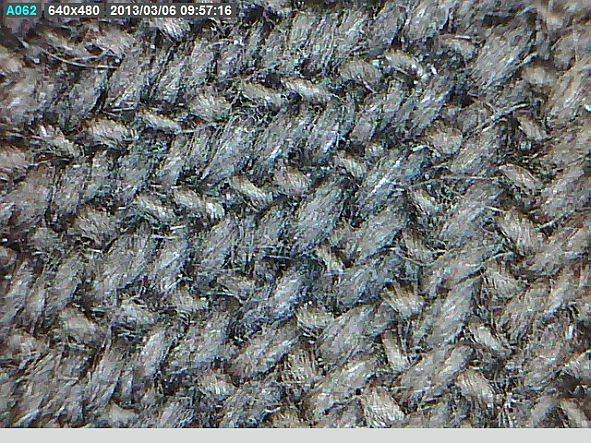

Twill

In twill and derived fabrics one woof thread alternates over two warp threads and further on over other two warp threads, but displaced by one position. It generates a characteristic design of oblique line spacing, or in case of interchange a fishbone design (Fig. 4).

Fig. 5 Photograph from microscope; two-colour twill (Photo NL CR)

Fig. 6 Photograph from microscope; Sateen weave (Photo NL CR)

A considerable number of varieties comes up from this basis then.

Twill used for book-binding purposes is in most cases double-sided coated and very often multi-coloured (Fig. 5).

Sateen weave (sateen)

Sateen weave is the third out of basic fabric weaves.

Thanks to the specific weave (so-called five-weave sateen), high gloss is characteristic for it, and at the same time low resistance to abrasion (Fig. 6, 7). Therefore, it is used rarely.

Fig. 7 Sateen cover ornamented with gilding (Photo NL CR)

Fig. 8 Simple recurrent design (Photo NL CR)

Fig. 9 Ornaments (Photo NL CR)

Fig. 10 Imitation of leather (Photo NL CR)

Coated (dressed) canvases

In case of book-binding canvases, and generally textile covers of bookbinding, coating is often used for finishing, which may be made of starch, acrylate, or latex. It is applied for surface protection against abrasion and water, for better handling, and for more intense colourfulness. Coat must fill in gaps between fabrics threads, and thereby ensure its imperviousness for glue, which will be used later within the frame of processing canvas for bookbinding.11 Book-binding canvases are then classified into one-side and double-side coated according to the application of coat. Using coat, it is at the same time made possible to decorate surface of canvas by various plastic patterns. Most frequent ornaments (Fig. 9) are flower motives, simple recurrent patterns (Fig. 8), or also structures imitating leather surface (morocco (Fig. 10), leather of snake, ray, crocodile, etc.). Surface of coat is sometimes after application still further finished by polishing. This process is called calendering. Plastic embossing on canvas is carried out by special punching calenders.

Double-side coated canvases

Double-side coated canvases are most often canvases with smooth surface. Underside used to be implied only with less smoothing, but it is possible to use the canvas for binding on both sides. Canvases, which have punched surface are called shagreens.12 Thin type of shagreen is shirting. Here also belong thick twills, originally marketed under trade name cotton duck, which were used mainly for big and heavy trade books and bindings of large atlases and pattern books.

One-side coated canvases

Canvases coated only from the right side are called the English ones. These canvases have a layer of coloured coat on the surface, while on the reverse, there remains natural white colour of the fabrics. In this treatment of canvas, also petite damages incurred e.g. by abrasion are easily recognizable.

Canvases coated on the reverse, so-called ecru canvases, provide excellent natural surface of fabrics. Natural flaxen or semi-flaxen canvases and balloon canvases (very gently woven canvases with narrow warp texture 13) are often treated in that way. It is worth mentioning also special type of book-binding canvases, so-called doublets (Krypton). They belong among one-side coated canvases, but their coat is partly replaced with backing with thin backing paper (backing is carried out with an acrylate dispersion or thermally activated glue). Advantage of these canvases is considerable range of colourfulness, which may be offered by textile material itself. Colours are fancy and surface is natural. On wetting with glue, canvases maintain dimensional stability. On the other hand, disadvantage is that embossing is difficult on untreated canvas surface.

Most frequent damages of 19th century prints

Damage of books depends on a number of factors. As the first factor, it is necessary to mention material composition and method of material production. Material composition of 19th century books is highly diversified, mainly with regard on used paper. During the 19th century, industrial revolution continued to proceed, when conversion of manual production processes to mechanical ones happened. Indeed, these changes affected also production of book materials, and book manufacturing itself. At the same time, pressure continued to reducing factory prices, which caused that cheaper and lower quality materials were chosen for books, durability of which was lower.

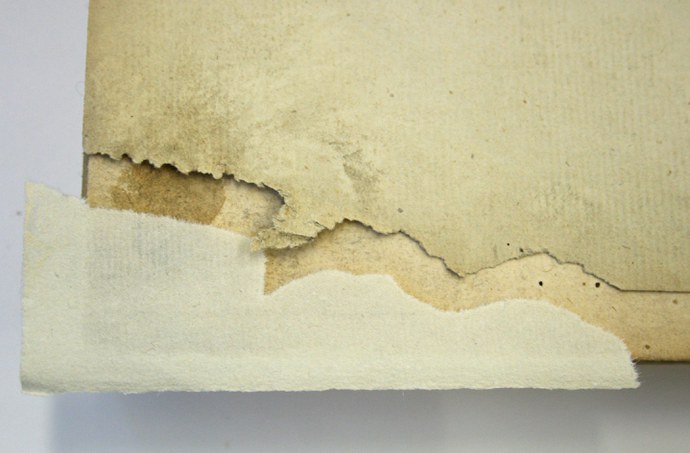

Because of lack of original raw material (rag) for paper production, wood began to be used as substitute. At first, wood was processed mechanically, resulting in wood pulp, which concerned as a problematic material. Papers, containing wood pulp are fairly recognizable because of yellowish and very breakable paper. Wood pulp had the greatest importance in production of paper for newspaper, which contained 75–80 % of wood pulp, abroad sometimes even 88 %. Disputableness of this paper was discovered very early, and that was why new and better processes were developed. Later, chemicals began to be used in wood processing. According to utilization of specific chemicals, resulting product, which was used for paper production, was called soda pulp, sulphite pulp, or sulphate pulp.15

Another factor, which affects type of damage, is unsuitable storage of books. If a book is stored in high relative humidity and high temperature environment, growth of moulds may occur, which are capable to convert paper into powder. Low humidity is also not suitable, because drying of organic material occurs, which then becomes breakable.16

A very important factor, which affects damage of books, is a human factor. Great damages of books are caused by faulty manipulation and unsuitable repairs. Therefore, it is very important to manipulate with books carefully and avoid unsuitable materials for repairs.

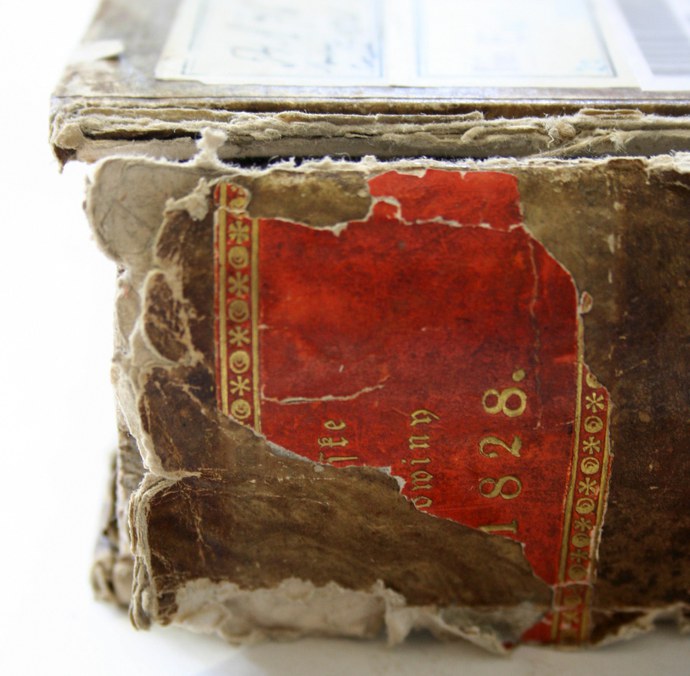

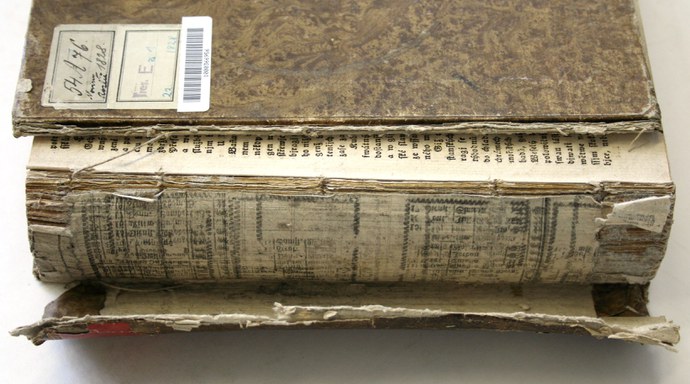

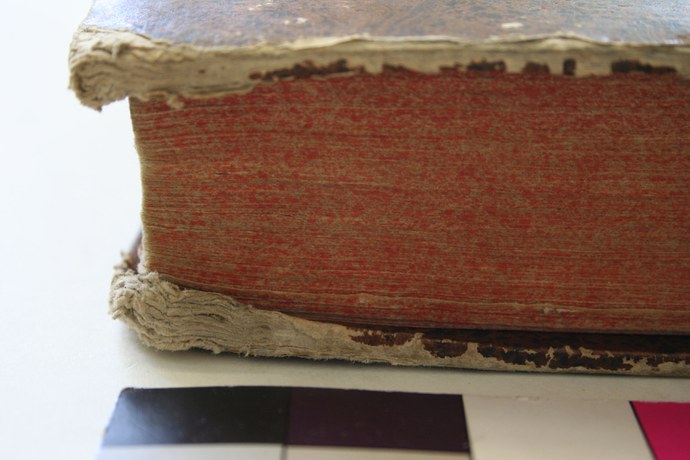

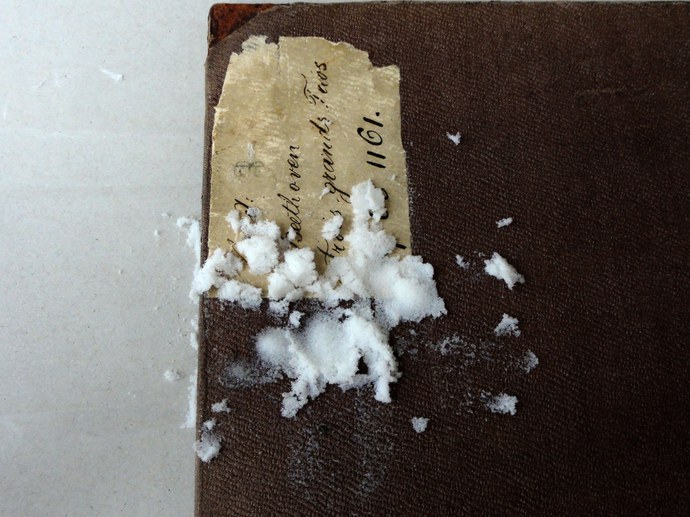

If we take into account all these factors when depositing documents, we can ensure better durability of greatly various book collections of the 19th century. Further, most frequent damages of books, are described and documented with illustrative photographs which may endanger their compactness or cause their further damaging. Over the years of usage, impurities deposit on book cover, e.g. dust, greasy stains, or stains from various liquids, often also leftovers.

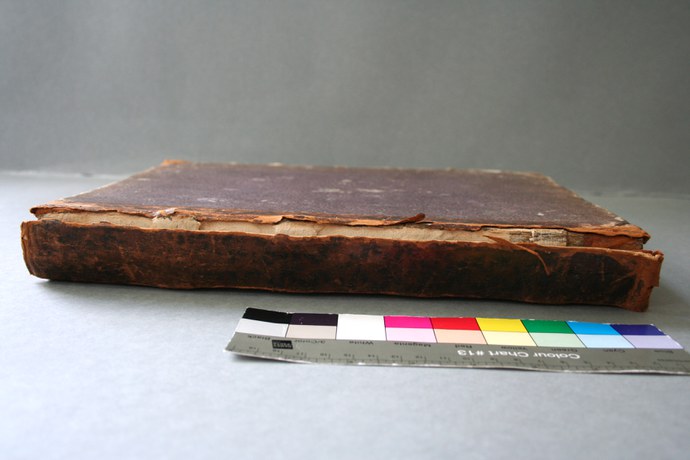

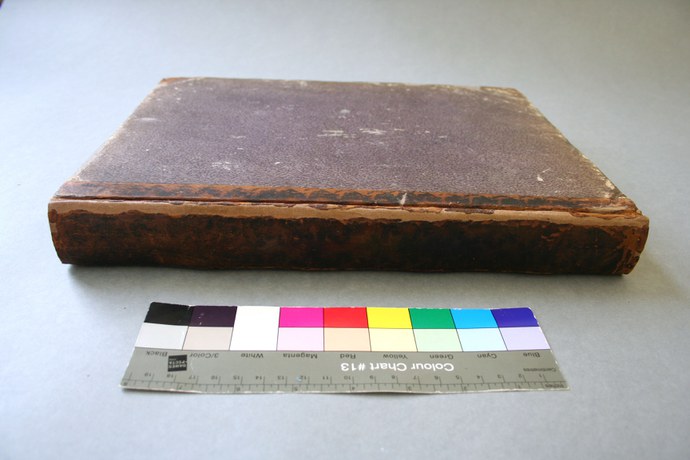

A frequented damage in spinal part of a book is a loss of headcaps, which comes up from thoughtless pulling books out from racks – pulling for headcaps.

Fig. 11 Damage of headcap (Fund NL CR)

When hinge cracks, spine lining from the board may pull away. The largest damage of spinal part of the book is complete loss of spine cover and back lining. When spine of a book is exposed, damage of sewing and folders may occur.

Fig. 12 Cracked back hinge and released board (Fund NL CR)

Cover abrasion and its waste occur by friction of books one about another in a rack. Wrong handling in repeated placing books in and their removal from racks may cause damage of edges and corners of boards. Absence of board or its part is very dangerous for book block. Paper of the first or the last folder is prone to damage.

Fig. 13 Abraded cover and its partial loss (Fund NL CR)

Fig. 14 Damage of edges and corners – waste of cover and layering (Fund NL CR)

The most frequent damages of book block are cracks and loss of sheets of paper. By turning the sheets in book we sometimes run across a sheet or folder ripped out from the book block. Lower corner of paper is also contaminated and weakened by frequent turning the sheets.

Fig. 15 Loss of sheet of paper (Fund NL CR)

Fig. 16 Ripped out folder from book block (Fund NL CR)

End papers made from wood-pulp and acidic paper often do not stand straining, and then their partial to total disruption in back joint occurs. If the end papers are made from higher quality paper than papers in the book block, disruption may occur in the first or the last folder. If backing sheets are completely cracked in the back hinge on the first or the last folder then all weight of the book block is transferred to cords. They cannot carry away the stress and their rupture occurs. If the cords crack the block disjoins from the front or the back board, or completely from the cover (Fig. 18).

Fig. 17 End paper cracked in the back hinge (Fund NL CR)

Fig. 18 Rupture of folder and cords in the book block (Fund NL CR)

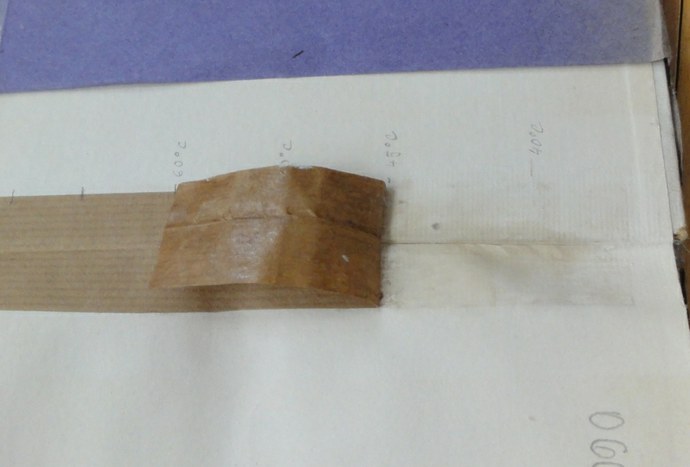

Unprofessional repairs by the help of adhesive tapes are very problematic, because further damage of bookbinding or book block may occur. Their removal is described in the next part of the text.

Procedures for preservation and cleaning 19th century prints

Technology of cleaning 19th century prints

Contamination represents a high risk of damage, speeding processes of degradation and undesirable reactions of individual components of paper, textile, leather and other materials occurring in binding structure of books. Basic assumption for stabilization of permanently preserved books is removal and elimination of contamination on the surfaces of used materials, as well as products of degradation coming out from material essence itself. Cleaning is generally one of optimal means for extension of durability of permanently preserved objects from economical and time consuming point of view. Selection of cleaning strategy of books from modern collections is subject not only to characteristics of contamination or physical conditions of the object, but also a measure of risk and time efficiency. Special emphasis is placed on protection of recording media, such as printing dyes, inks, Chinese ink, stamping dyes, and others. Dust is most widespread contamination in book collections. Dust is a mixture of many substances, which negatively affect conditions of materials forming book block. In addition to salts, soot, grease, and compounds of metals (iron, lead, cadmium), also germs of microorganisms are present in dust. Capability of dust to absorb aerial moisture and fixate it on paper surface contributes to activation of transition metals and acids.17 Contamination caused by book usage is another problem. First of all it concerns contamination of sheet corners from finger grease, leaking in beverages, and stains from foodstuff. Contamination of books caused by thoughtless handling occurs also very frequently, as well as by natural disasters, biological factors, water, wax, resins, and materials, which got into the book blocks during its usage (plants, insects, etc.). Products of degradation or corrosion of bookbinding materials also belong among contaminations.

Methods of cleaning can be divided to mechanical methods (dry cleaning), cleaning with water systems, and cleaning on the basis of chemical reactions, such as cleaning by the help of organic solvents.18

Mechanical cleaning

Mechanical cleaning removes particles of impurities deposited on paper surface, such as dust. Efficiency of cleaning agents is affected by cohesion of impurities on paper surface. Each of cleaning agents has its specificity, and selection is then subject to the type of impurities, structure of contaminated material, and conditions of material to be cleaned. Basic cleaning of dust is carried out with brushes and vacuum cleaners with brush adapters. This procedure is preferred above all in collective interventions (moving collections, refurbishment of depositories, or research laboratories, etc.). This method is reliable for all types of books, as long as it is carried out with proper care and with respect to the book conditions. Cleaning with brushes and vacuum cleaners removes only part of dust deposits and other impurities on the surface.19 Impurities difficult to remove are, therefore, removed by more efficient means. They can be divided into compact cleaning agents (rubbers, sponges, blocks of cleaning materials), plastic cements, powdery cleaning agents, and electric cleaners.

Fig. 19 Means for mechanical cleaning (Fund NL CR)

Slabs or rollers of modified PVC – material PURUS - are of universal usage. Their cleaning capability consists in sticky surface, on which particles of impurities are trapped. Sponge Wallmaster is another aid in use made of clean latex rubber, featuring porous structure, which increases sticky surface of sponge at the most. Rubbers Wishab based on vulcanized latex are sticky and are lightly scrolled out. Therefore, they do not strain material surface to be cleaned so much, but surface must be subsequently cleaned using a vacuum cleaner from pulverized particles.20

Fig. 20 Cleaning of paper using sponge Wallmaster (Fund NL CR)

Thanks to their strong cohesion, cleaning cements have ability to attach impurities on their surface. Plastic structure makes it possible to adsorb impurities into mass of cement, whereby period of its using extends. However, strong cohesion causes also undesirable uplift and peeling of minute particles of materials with less cohesive surface, for example threads in insufficiently glued papers.

Agents in powdered form are represented primarily by crushed rubbers of various grain size. They are regardful to surface of treated materials, and have good capability to adsorb surface impurities. Their disadvantage is that they are difficult to remove, therefore, rubber powders are applied at those sites of bookbinding, which are easily accessible. Within the frame of project NAKI, application of material Perlóza is tested for cleaning paper and textile elements in the workplace of the Division of Preventive Conservation. Pure regenerated cellulose in the form of ball-shaped, highly porous micro-elements can be saturated only with water or with addition of suitable tenside. Combination of porous surface of polymeric elements and sorption capabilities makes possible to remove solid impurities (such as e.g. dust, various deposits on the surface), but also organic substances. Indeed, cleaning is mechanical, but with regard to the principle of cleaning, where there is necessary presence of water, this method can be found in the division line between mechanical cleaning and cleaning with water systems.

Fig. 21 Application of pearl cellulose on book cover (Fund NL CR)

Electric rubber machine is relatively penetrative cleaning tool, and its application is subject to good compactness of paper surface, it is not used for other materials. Efficiency of this manual machine is given by the type of rubber filling (white soft rubber, abrasive rubber, so-called plastic rubber, etc.).

Cleaning with water systems

By the help of water and water solutions, not only impurities on the surface are removed, but also soluble matters and degradation products of the material. Cleaning with water systems is preceded by mechanical cleaning for removal of soluble deposits on the surface. Using water system in bookbinding is questionable. Only loose sheets are treated in this way, which do not contain water soluble dyes. Solubility of dyes is tested before initiation of cleaning. After cleaning paper in water bath, the paper is glued with glue based on cellulose ether, for example Tylose MH300 (0.5% aqueous solution). Cleaning of unbound books with water is possible on restorers´ workplace equipped with special vacuum chock, on which paper is washed with water, which may be in form of vapour or aerosol. Moistened materials are used for local application of water solutions, as cotton-wool swabs and extremely absorbing sponges (e.g. Blitzfix, Conservation Sponge, etc.), by which it is possible to clean not only paper, but also textile, exceptionally also leather. Demineralized or distilled water is used for cleaning. Drinking water contains ions of metals, minerals, and other substances, which may reduce cleaning efficiency, and bring undesirable elements into materials to be purified. Water itself is not sometimes capable to remove some sorts of impurities, therefore, various types of surfactants – tensides - are added to baths. Tensides used should always be washed out by pure water from any material.

An alternative to cleaning unattached papers in bath is cleaning on capillary textile. Advantage of this method is that paper is not mechanically stressed, and loosening of threads or cracks does not happen. The principle of cleaning is based on capillary rise of water in textile with synthetic threads laid in one direction, on which contaminated unattached sheet of paper is placed. By capillary action water migrates through capillaries and takes away soluble impurities from paper to the textile, and subsequently to the collecting vessel. 21

Application of hydrogels also belongs among cleaning with water systems. Water is partly fixed in gel, and quantity of water penetrating into paper is more or less controlled (depending on gel concentration). Impurities and degradation products are absorbed by gel. By addition of deacidifying solution into gel, it is simultaneously possible to deacidify paper within the frame of cleaning. Compared to water bath, this type of cleaning is thoughtful, deformations, slackening of fragments and tearing of paper do not happen. This procedure is used on loose sheets of paper at present, but also local removal of impurities not only from paper is under testing.

In case of coating materials, cleaning with water solutions is possible only locally so that activation of glue and materials in lower layers under the coat does not occur. If cleaning with water systems is possible according to found temperature of shrinkage 22 of leather, and non-aqueous agent cannot be used for some reason, surface of leather may be treated with foam of water solution of non-iogennic tenside (Alvol) in soft natural sponge. Cleaning foam must be swiped out immediately with clean sponge or cotton swab saturated with water, and leather then dried using a suitable absorbent material.

In cleaning, leather must not be soaked with excess of water. After water content in leather achieves the value of 17–20 %, leather must be greased with selected grease mixture. If metal elements are present in bookbinding, mechanical cleaning is preferred, or cleaning by the help of organic solvents.

Chemical cleaning

Chemical cleaning and use of organic solvents require a workplace equipped with air conditioning, and it is necessary to work with means of protection. Organic solvents are used first of all for local removal of stains, varnishes, resins, and greasy spots. Just as with cleaning with water system, also in this case solubility of present dyes is tested. In 19th century collections, the processes are not carried out such as whitening of paper, etc. For textile materials, medical grade benzine may be used. Isopropyl alcohol is non-hazardous agent for cleaning of leather. Commercial anhydrous cleaning agents are also manufactured for leather, specialized for leather with a definite type of tanning, or for white leather and parchments.

Tab. 1 Use of selected solvents for impurities on paper

| Type of contamination | Organic solvent |

| Greasy stains | Benzine |

| Varnishes | Acetone |

| Wax and oil stains | Hexane and toluene |

| Synthetic self-sealing tape | Benzine, acetone |

Restoration of 19th century prints

In restoration 19th century book collections, it is important to take into account various materials, which can be found in these collections. Immense amount of books in modern collections are another specifics, therefore, in contrast to collection of historical books, we must approach restorers´ intervention in a different manner than it is customary in procedures used for restoration of historical books.

Photographic documentation is the first step, as well as survey of the book damage, according to the results of which it will be decided, how the restorers´ intervention will further proceed. It is important to consult every restorers´ procedure with the collection administrator, who knows how great the book has signification, and how it is valuable. Creation of new historicist binding can be approached in books, which have non-functional binding. Partial restorers´ progress is preferred, compared to the complex one, because in case of the latter it concerns a time consuming process. At the same time great emphasis is placed on functionality of the book, therefore, restorers´ intervention must enable its follow-up usage.

The next step is cleaning, both mechanical and by the help of water systems, which is carried out largely locally, if the book is heavily contaminated. Cleaning has already been described in more detail above. Old repairs are not removed, if they are functional, and do not further damage the book.

It is impossible not to miss out pH-value measurement of paper in books from 19th century, because saponified resin with alum was began used for sizing of paper at the beginning of that century, which cause today's acidity of paper. Suitably selected and carried out method of deacidification may extend lifetime of paper by hundreds of years. In great amount of books it is advisable to use mass methods of deacidification.23

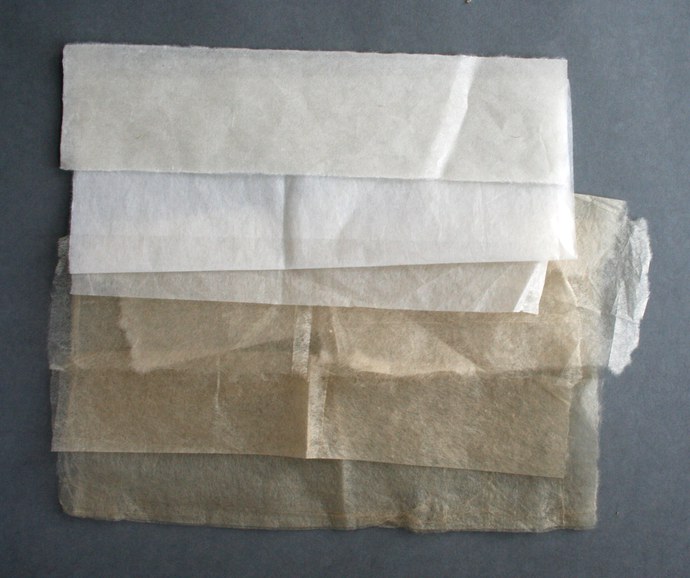

The subsequent step is reparation of book block. For corrections of cracks in paper, coloured Japanese paper is used, basic weight of which is selected according to thickness of the original sheet.

Fig. 22 Japanese papers (Author´s archive)

Missing places are filled by the help of overlaying Japanese paper or analogous hand-made paper. Starch or cellulose ethers (Tylose MH 6000) proved good as suitable glue. Patching is accelerated by the help of restorer´s spatula with thermoregulator.

Fig. 23 Filling losses with hand-made paper (Author´s archive)

If the book block is repaired and sewing of the block is functional, repair of cover may be approached. Small losses of covers in corners may be repaired by the help of heavy paper suspension. Loose layers of corners and edges of covers are glued one to another using starch, and they are afterwards fixed by the help of pasteboard and clamps, until desiccation occurs.

Fig. 24 Repair of missing corner of the cover by heavy suspension of paper pulp (Author´s archive)

Missing parts of paper layer of the cover are complemented by Japanese paper of higher basic weight, which is coloured so that the reparation was apparent, but does not disturb integrity of the book.

We always endeavour to put in the filling under the original cover. Starch or cellulose ethers may be used again as suitable glue.

Fig. 25 Filled part of missing paper cover (Author´s archives)

When repairing non-existent parts of spine cover of whole-bound in cloth or half-cloth bindings, canvas is used, which is most similar to the original, which means, it should have the same colourfulness, surface finish, and texture of warp and woof. Nowadays, it is very problematic to obtain identical canvas, therefore, suitably coloured Japanese paper can be used backed with thin cotton canvas (batiste, thin shirting, crepeline, 24 etc.). In cooperation with the Technical University in Liberec, a suitable material is being developed at present, which would complete missing places and, at the same time, it has similar appearance as the original canvas. As a basic material a textile material without weave (so-called unwoven textile) was chosen, which is sufficiently firm, and at the same time thin, and in some properties it exceeds Japanese paper. The resulting appearance of the applied textile will be possible to adapt by suitably coloured coat, into which a pattern of surface finish of the original cover may be impressed. This method is ideal in case of coated canvases with a pattern, but it very well substitutes also canvases without pattern.

If back lining is missing, it is replaced with new one from non-acid stiff paper.

Fig. 26 Japanese paper backed with glued canvas (Author´s archive)

In leather and half-leather books, which suffer from loss of cover in spine of a book, it is possible to replace missing parts with paring leather of similar colour tone. As an alternative, it is possible to use Japanese paper backed with canvas.

Fig. 27 Half-leather book with cracked back hinge – before restoration (Fund NL CR)

Fig. 28 The same book after restoration (Fund NL CR)

The last step is creation of a suitable cover for depositing, which will protect book in handling, and will partly prevent settling of dust directly on books. Alkaline millboard of archival grade is always selected as a material of cover.

The most frequent restorers´ operations were described above, however, this procedure cannot be considered as an unchanging rule, because every book is unique, and with this in mind it must be approached.

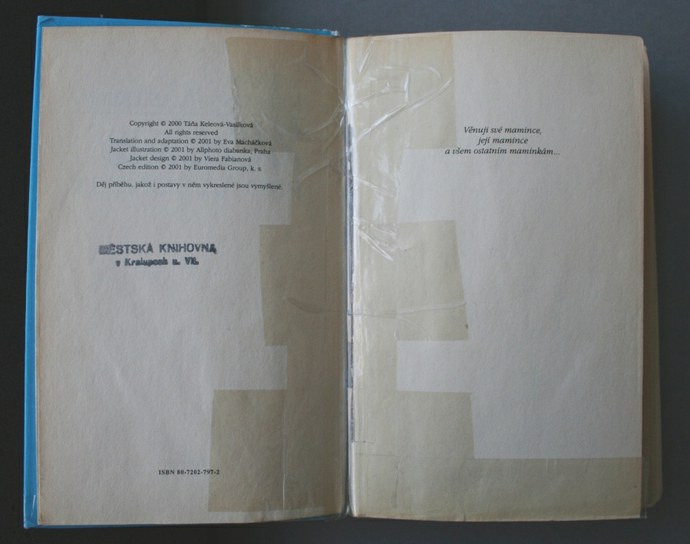

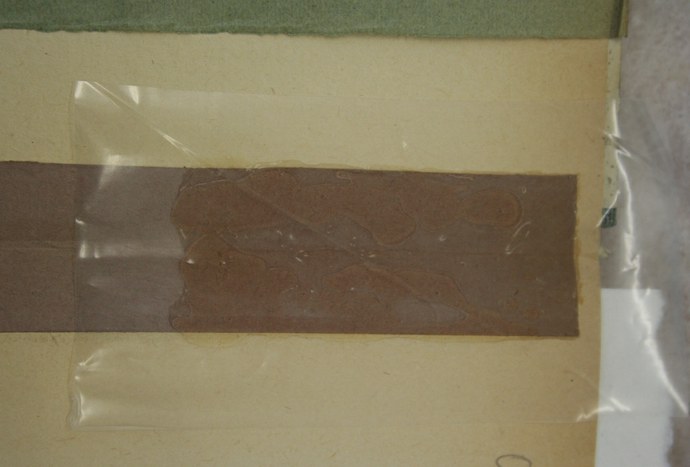

The most frequent unprofessional intervention – use of adhesive tapes for reparations of books and problems of their removal

Unprofessional attempts to repair damaged books by the help of readily available office and corrective adhesive tapes are frequent phenomena in library collections and not only of modern ones (Figs. 29, 30). These interventions are usually carried out with the intention to extend lifetime of books, and to renew their original functionality. However, these interventions in result affect document not only visually, but also negative changes of mechanical and chemical properties occur. In the process of aging, hazardous substances release from tapes, which irrevocable damage paper and other materials connected with bookbinding.

From the above mentioned reasons, it is always desirable to remove already applied adhesive tapes. Removal should be carried out as considerately as possible, with intention to remove the largest possible quantity of adhesive layer.

Fig. 29 Example of unprofessional repair (Fund NL CR)

Fig. 30 Example of unprofessional repair (Fund NL CR)

Adhesive tapes are made of elastic support material (plastics, paper, textile, etc.), and glue. Adhesive layer may be made of various materials, both natural and synthetic, with different activation.

Tapes can be divided into tapes with water activated glue, which are largely on paper support, textile may be also used. Glue used is generally of animal origin (glue, gelatine), but there are also tapes with dextrine glue. Other types of tapes are heat activated, where the support is Japanese paper as a rule. The example is correction tape Filmoplast R. The most widespread and very problematic are self-adhesive tapes activate by pressure. Generally, in the Czech Republic, this type is incorrectly called "izolepa".

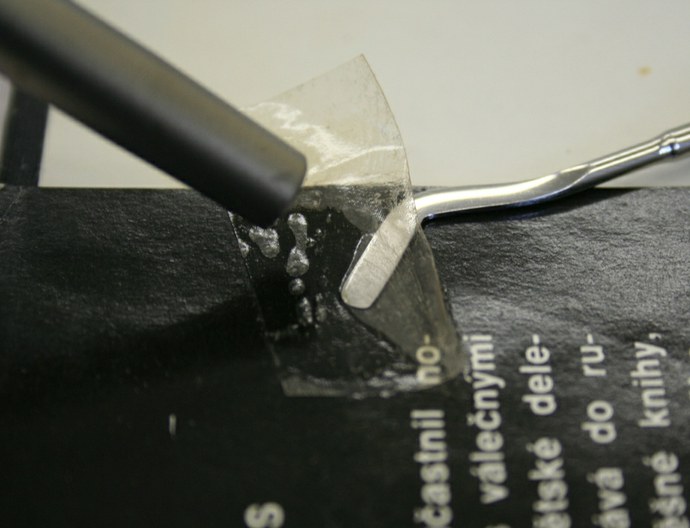

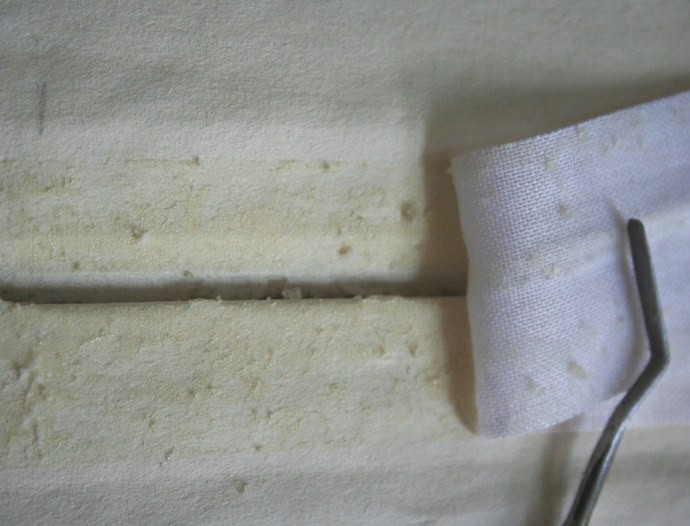

Techniques of removal

a) mechanically

b) with water and water solutions of cellulose ether

c) with organic solvents and their solutions

d) with steam or aerosol of various temperatures

e) by hot air

Proven procedures for tape removal

Different approach is necessary for tapes of different types. For paper tapes with water activated glue, Tylose MH6000 was most often applied, further, aqueous aerosol at various temperatures, and distilled water. In self-adhesive tapes activated by pressure, removal is more complicated with respect to variety of glues and supports. In most cases it is necessary to combine mechanical removing with the use of solvents.

Aqueous aerosol of different temperatures was tested on paper tapes (Fig. 31). In this procedure, there is an advantage of possibility to direct flow of aerosol according to the needs, and increase or decrease its intensity. It is important that the moisture gets as far as the glue layer. It is then ideal to moisten surface of the tape with aerosol and let it sufficiently soak. After it, it is possible to remove the tape by mere pulling. Time of removal is in this case comparable to that of other procedures of removing with water and water solutions. Aerosol temperatures were examined of values of 40 and 50 °C. In both cases the results were the same.

If the tape is removed with distilled water, which is applied using a brush or a cotton swab, the principle is the same as that of the previous procedure. The tape should be moisten and let sufficiently soak.

The most comfortable technology of removing paper tapes based on glue or gelatine is using Tylose MH6000. It concerns cellulose ether soluble in water, used for gluing or sizing of paper. Aqueous solution of 5 % Tylose proved good when applied in a thick layer on tape and left for a period of ca. 10 min covered with plastic foil (Fig. 32). The tape was released and removed by pulling.

In case of aqueous aerosol and distilled water, also threads of paper tape cling to the sheet of paper together with glue. In case of Tylose MH6000, tape was withdrawn with larger quantity of glue, the spot was after cleaning visibly lighter (the cleanest). In all cases after withdrawal of tape, it is necessary to finish cleaning of the spot by the help of cotton swabs or wood-pulp and distilled water.

Fig. 31 Removing glue tape with aqueous aerosol (Fund NL CR)

Fig. 32 Removing glue tape with 5% Tylose MH6000

In removing tapes with glue layer activated by pressure, use of hot-air gun proved best. The best results were achieved at 60–80 °C (Fig. 33). The support is usually removed together with large quantity of glue, and cleaning of the spot is then finished with cotton swabs moistened in some solvent. Selection of solvent depends first of all on print solubility. Prior to any application, it is necessary to test solubility on a small, less visible spot. Best results in removing adhesive layers were achieved by the help of benzine of medical grade, in which solubility of the print is not so frequent, as, e.g. in acetone or ethyl alcohol. It was found out from the results of analysis of adhesive layers of tapes taken from books discarded from the collections of NLCR that in tapes, glue on acrylate basis has the largest representation. These tapes were most frequently removed just by hot air, and final treatment of the spot was achieved by benzine of medical grade. Further, other readily available solvents were examined, as ethyl alcohol, acetone, xylene, isopropanol, or toluene (Fig. 34). In case that the tape is impossible to take away by hot air, and it is necessary to intervene with solvents, it is advisable to start in small sections by moistened cotton swabs. If the solvent is applied with a brush, there is a risk of unwanted trickles of larger drops. It may cause maps or dissolution of glue, and subsequent soaking into paper.

Fig. 33 Removing plastic adhesive tape by hot air (Fund NL CR)

Fig. 34 Removing cloth tape by toluene (Fund NL CR)

Instruments used

Preservation pencil

Aqueous aerosol generated by ultrasonic moistener flows through heating head, in which it is heated to required temperature. It can be set by means of connected thermoregulator. Variable adapters to the head nozzle are also part of the delivery.

Hot-air gun Hot-Jet S

It is specially designed for use in restorers´ processes for removing glues, adhesive tapes, desiccation, etc. Air temperature is adjustable from 20 to 600 °C. Air quantity can be set from 20 to 80 l/min. It is possible to buy various types of adapters to the gun.

Corrective tapes

Tapes with guaranteed service life used presently for fast repairs of paper were introduced to market only several tens of years ago. Filmoplast P belongs among the most widely used, which is together with Filmoplast R product of German company Neschen AG.

Filmoplast P is highly transparent self-adhesive foil equipped on one side with non-acid adhesive layer. Thin transparent paper (20 g/m2) serves as a support, which does not contain wood-pulp. Self-adhesive layer is formed of permanently elastic acrylate glue (acrylate copolymer), pH of which is modified using calcium carbonate to approximate value of 8.5.25

Removing Filmoplast P tape is very difficult, and success depends on duration of time elapsed from application of the tape, type of paper, and sensitivity of coloured layers. The tape is impossible to remove completely all at once. First, paper support is removed, and subsequently glue by the help of tools and an organic solvent. While using organic solvents acetone, ethyl alcohol or toluene, formation of maps on paper and dissolving printing colours occur (Fig. 35). Use of isopropyl alcohol and xylene is less hazardous. By the help of benzine of medical grade, it is possible to remove glue only from papers with surface finish, such as e.g. lamination. In this case glue swells rather than dissolves, and forms lumps, which it is possible to remove only from smooth surfaces.

With respect to the found facts, it is impossible to consider Filmoplast P tape as a reversible one, and its usage is impossible to recommend for repairs of books and other documents on paper from collections intended to long-term or permanent preservation. Its utilization should be considered also in copies, which may be registered to the named group of collection in future.

Fig. 35 Removing adhesive layer by toluene (Fund NL CR)

Filmoplast R is a transparent laminating foil, equipped on one side with heat activated layer. It is colourless, resistant against aging, it does not get yellow, and does not damage colours. Foil is intended for heat lamination of newspaper and other paper materials made after 1840. It is not recommended for hardening documents of older dates, or for historically valuable archive materials.

The support is very thin transparent technical Japanese paper (8.5 g/m2), without content of acid substances, lignin, or hemicelluloses, on the other hand, it disposes of high content of alpha-cellulose. Adhesive thermoplastic layer consists of acrylate copolymer. The layer does not contain softeners, pH value is modified using magnesium carbonate.26

For application of Filmoplast R, it is necessary to own restorer´s spatula (e.g. Hot Iron or RTC-2 with thermoregulator), or laminating machine for full-area lamination. Adhesive layer of the tape is activated by heat, and it adheres to paper. For perfect adhesion, it is necessary to set temperature on the thermoregulator to ca. 120 °C, otherwise the tape will not adhere entirely, and in addition to increased opacity, there is also risk of releasing from the support. It generally applies that the higher is temperature in application, the better the tape adheres, and it is less visible. At lower temperatures, bigger pressure is necessary to apply.

Removing Filmoplast R is considerably easier than in case of Filmoplast P. Tape can be removed by hot-air gun, using the same temperature as when it was applied, then ca. 120°C (Fig. 36). Residue of glue can be removed from paper mechanically. Another option is utilization of organic solvents. In testing capability to remove tape, benzine proved the best, which does not solve printing and does not create maps. Further, acetone was tested, by which the tape can be easily removed, however, in less glued or wood-pulp paper, there is risk of dissolving text and creation of maps.

Fig. 36 Removing Filmoplast R by hot air (Fund NL CR)

Conclusion

Partial results of grant project NAKI "Survey, conservation, and care for modern library collections – materials and technologies" acquired during 2013–2014, are presented in the paper. Testing of methods of conservation and restoration of modern book collections, or 19th century prints, will continue also in the following three years. The results of research and testing of interventions should make care for these rare books more efficient, extend their lifetime, and preserve them in good physical conditions for readers – the main objectives of all activities in this project is functionality of bookbinding and its preservation.

References:

BENEŠOVÁ, Marie. Testování účinnosti běžných způsobů mechanického čištění papíru. In: Fórum pro konzervátory a restaurátory. Brno: Metodické centrum konzervace, Technické muzeum v Brně (Effectivity testing of common methods of mechanical cleaning of paper. In: Forum for conservators and restorers. Brno: Methodical centre of conservation, Technical museum in Brno), 2014. s. 50–55. ISSN 1805-00050, ISBN 978-80-87896-08-2.

ČSN 80 4565. (Czech State Standard). Bavlněné tkaniny (Cottons).Vydavatelství úřadu pro normalisaci, Praha (Publisher of the Institution for standardization. Prague),1955.

DONÁT, Adolf. Materiály na výrobky z papírů a lepenek. (Materials for products made of paper and millboard). First edition. Brno: State publishers of technical literature), 1963.

ĎUROVIČ, Michal. Restaurování a konzervování archiválií a knih. (Restoration and conservation of archival documents and books). 1st edition. Prague, 2002, 517 p. ISBN 80-718-5383-6.

Filmoplast® P. [online] [ref. 2014-05-25]. Accessible from::

http://www.neschen.de/assets/ProductDB-Import/Download-207/dats_sheet_-_filmoplast_p.pdf.

[ Filmoplast® R. [online] [cit. 2014-05-25]. Accessible from::

http://www.neschen.de/assets/ProductDB-Import/Download-261/data_sheet_-_filmoplast_r.pdf.

KRÁL, Jindřich. Moderní knihařství: Souborné zpracování poznatků oboru. (Modern bookbinding: Cumulative processing of branch pieces of knowledge). First edition..Brno: SURSUM, 1999. ISBN 80-85799-49-9.

LEDERLEITNER, Milan, Josef HAMAR a Vladimír THOMKA. Polygrafické materiály pro I.–III. ročník SOU. (Polygraphic materials for 1 – 3 grades of Secondary Technical Training Centre). 1st edition. Prague: State Pedagogical Publishers Prague, 1990. ISBN 80-04-24132-8.

SCHALKX, Hilde, Piet +-+--- LEDEMA, Birgit REISSLAND a Bas van VELZEN. Aqueous treatment of water-sensitive paper objects. In Journal of Paper Conservation. Vol. 12, No. 1. Stuttgart, Germany: IADA, 2011. pp. 11–20. ISSN 1868-0860.

SOUČEK, Milan. Exkurze do papírny. (Excursion into papermill).Prague: State Publishers of Technical literature, 1963, 179 p.

TEPNA, Cotton plant, National enterprise. Vzorkovnice kniharských pláten (Sample book of bookbinders´ canvases). Česká Skalice, 1969.

VÁVROVÁ, Petra, Jiří POLIŠENSKÝ, Pavel KOCOUREK a Hana SEDLISKÁ. Metodika průzkumu fyzického stavu novodobých knihovních fondů. Certifikovaná metodika. (Methodology of survey of physical conditions of modern book collections). Certified methodology. Available from:

http://text.nkp.cz/o-knihovne/projekty-a-programy/vyzkum-a-vyvoj-naki/virtualni-depozitni-knihovna/jednotlive-cinnosti-v-projektu-vdk/certifikovane-metodiky/metodika-pruzkumu-fyzickeho-stavu-novodobych-knihovnich-fondu/metodika-pruzkumu-fyzickeho-stavu-novodobych-knihovnich-fondu/view.

VÁVROVÁ, Petra, Jiří POLIŠENSKÝ, Pavel KOCOUREK, Hana SEDLISKÁ, Magda SOUČKOVÁ, Lucie PALÁNKOVÁ a Věra POSPÍŠILÍKOVÁ. Nový nástroj pro monitorování fyzického stavu knihovních fondů (A new tool for monitoring physical conditions of book collections). Knihovna (Library) [online]. 2012, vol. 23, No. 2, pp. 66–76 [ref. 2015-03-16]. Available from: http://knihovna.nkp.cz/knihovna122/neuvirt.htm. ISSN 1801-3252.

Wishab Dry Cleaning Sponges. [online]. [cit. 2014-10-30]. Available from:

http://www.conservationresources.com/Main/uk_section_012/012_018.htm.

1 Workplace of the authors: The Collection Preservation Division, the National Library CR

2 http://katif.nkp.cz/Katalogy.aspx?katkey=050BIBL19

3 http://katif.nkp.cz/Katalogy.aspx?katkey=050BIBL19

4 PhDr. Jiří Polišenský, Director of Division of Book Collection Management of NL CR in 1994 - 2012.

5 Register of digitization – current infrastructure of the Register of digitization is used, specifically a storage site – RDBMS ORACLE, and search system MS FastSearch is used as presentation interface.

6 VÁVROVÁ, Petra, Jiří POLIŠENSKÝ, Pavel KOCOUREK, Hana SEDLISKÁ, Magda SOUČKOVÁ, Lucie PALÁNKOVÁ and Věra POSPÍŠILÍKOVÁ. Nový nástroj pro monitorování fyzického stavu knihovních fondů (A new tool for monitoring physical conditions of book collections). Knihovna (Library) [online]. 2012, vol. 23, No. 2, pp. 66–76 [ref. 2015-03-16]. Available from:http://knihovna.nkp.cz/knihovna122/neuvirt.htm. ISSN 1801-3252.

7 VÁVROVÁ, Petra, Jiří POLIŠENSKÝ, Pavel KOCOUREK and Hana SEDLISKÁ. Metodika průzkumu fyzického stavu novodobých knihovních fondů (Methodology of survey of physical conditions of modern book collections). Certified methodology. Available from: http://text.nkp.cz/o-knihovne/projekty-a-programy/vyzkum-a-vyvoj-naki/virtualni-depozitni-knihovna/jednotlive-cinnosti-v-projektu-vdk/certifikovane-metodiky/metodika-pruzkumu-fyzickeho-stavu-novodobych-knihovnich-fondu/metodika-pruzkumu-fyzickeho-stavu-novodobych-knihovnich-fondu/view.

8 Coat is an elastic, firm film of one or more layers, which is laid on by paintwork on fabric. Considerably increases resistance of textile against dampness. Canvas are then called coated (dressed) canvas, or canvas with coat.

9 DONÁT, Adolf. Materiály na výrobky z papírů a lepenek (Materials for products made of paper and millboard). First edition. Brno: State publishers of technical literature, 1963.

10 CSN 80 4565 (Czech State Standard). Bavlněné tkaniny (Cottons).Prague: Publisher of the Institution for standardization, 1955.

11 KRÁL, Jindřich. Moderní knihařství: Souborné zpracování poznatku oboru (Modern bookbinding: Cumulative processing of branch pieces of knowledge). First edition. Brno: SURSUM, 1999. ISBN 80-85799-49-9.

12 TEPNA, Cotton plant, National enterprise. Vzorkovnice kniharských pláten (Sample book of bookbinders´ canvases). Česká Skalice, 1969.

13 Warp texture represents data on a number of threads falling on one centimetre or inch of given fabrics. Therefore, it expresses weaving "density".

14 LEDERLEITNER, Milan, Josef HAMAR and Vladimír THOMKA.Polygrafické materiály pro I.–III. ročník SOU (Polygraphic materials for 1 – 3 grades of Secondary Technical Training Centre). 1st edition. Prague: State Pedagogical Publishers Prague, 1990. ISBN 80-04-24132-8.

15 ĎUROVIČ, Michal. Restaurování a konzervování archiválií a knih (Restoration and conservation of archival documents and books). 1st edition. Prague: Paseka, 2002, 517 p. ISBN 80-718-5383-6. SOUČEK, Milan. Exkurze do papírny (Excursion into papermill).Prague: State Publishers of Technical Literature, 1963, 179 p.

16 ĎUROVIČ, Michal. Restaurování a konzervování archiválií a knih (Restoration and conservation of archival documents and books). 1st edition. Prague: Paseka, 2002, 517 p. ISBN 80-718-5383-6.

19 BENEŠOVÁ, Marie. Testování účinnosti běžných způsobů mechanického čištění papíru. In: Fórum pro konzervátory a restaurátory. Brno: Metodické centrum konzervace, Technické muzeum v Brně (Effectivity testing of common methods of mechanical cleaning of paper. In: Forum for conservators and restorers. Brno: Methodical centre of conservation, ČSN 80 4565 Technical museum in Brno, 2014. pp. 50–55. ISSN 1805-00050, ISBN 978-80-87896-08-2.

20 Wishab Dry Cleaning Sponges. [online]. [ref. 2014-10-30]. Obtainable from:http://www.conservationresources.com/Main/uk_section_012/012_018.htm.

21 SCHALKX, Hilde, Piet LEDEMA, Birgit REISSLAND and Bas van VELZEN. Aqueous treatment of water- sensitive paper objects. In Journal of Paper Conservation. Vol. 12, No. 1. Stuttgart, Germany: IADA, 2011. pp. 11–20. ISSN 1868-0860.

22 Temperature of shrinkage is temperature at which bonds inside molecules of collagen slacken at heating in water, and shrinkage of collagen threads occurs. Value of temperature of shrinkage provides basic idea about degree of leather damage. If temperature of shrinkage is low (below 40°C), damage can occur in contact of treated leather with water. The National Library CR is the only cultural institution in the Czech Republic, where measurement of this quantity is carried out.

23 ĎUROVIČ, Michal. Restaurování a konzervování archiválií a knih (Restoration and conservation archival document and books). 1st edition. Prague: Paseka, 2002, 517 p. ISBN 80-718-5383-6.

24 Crepeline is a type of textile for restoration.

25 Filmoplast® P. [online] [ref. 2014-05-25]. Accessible from:http://www.neschen.de/assets/ProductDB-Import/Download-207/dats_sheet_-_filmoplast_p.pdf.

26 Filmoplast® R. [online] ref. 2014-05-25]. Accessible from:http://www.neschen.de/assets/ProductDB-Import/Download-261/data_sheet_-_filmoplast_r.pdf.